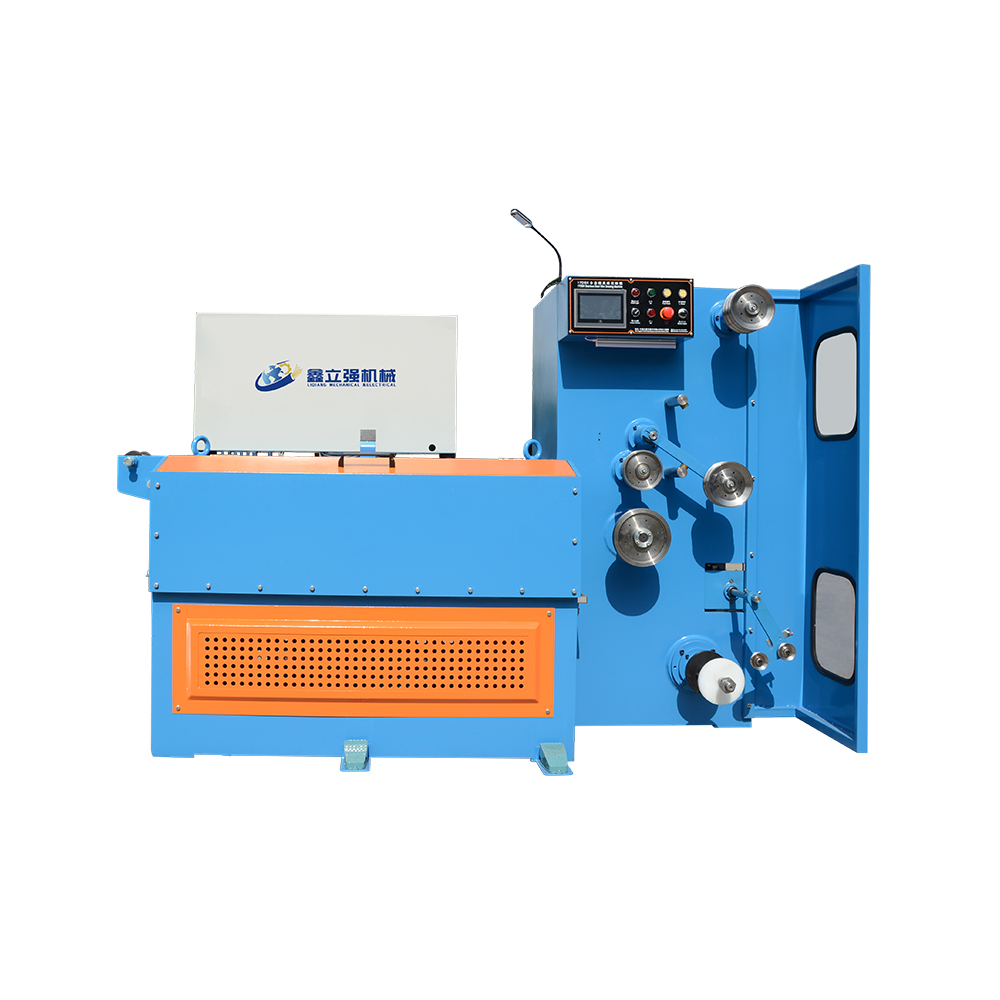

450/13-2DT เครื่องแยกส่วนแบบก้านพร้อมระบบขับเคลื่อนแยกกัน

Cat:เครื่องวาดลวดทองแดง

เครื่องนี้ส่วนใหญ่จะใช้สำหรับการวาดแท่งทองแดงขนาด 2 * Φ8มม. เป็น 2 * Φ1.6มม. - Φ4.0มม. (หรือแท่งทองแดงขนาด 1 * Φ8มม. ที่วาดเป็นลวดทองแดงสว่างอ่อนที...

ดูรายละเอียดSteel Wire Drawing Machines play a critical role in ensuring that the final wire products meet stringent industry standards for quality. As a manufacturer, you understand that the wire drawing process isn’t just about shaping steel; it’s about achieving precision, consistency, and reliability. With the right machine, the finished wire can exhibit qualities such as enhanced tensile strength, smooth surface finish, and optimal flexibility. But how exactly do modern machines contribute to achieving these results, and what role do advanced features play in improving quality control?

At the core of quality control is the ability to monitor and adjust the drawing process in real-time. Today’s Steel Wire Drawing Machines, equipped with cutting-edge technologies like PLC (Programmable Logic Controllers) and HMI (Human Machine Interfaces), make it easier than ever to fine-tune the process. These systems allow operators to set precise parameters for drawing speed, wire tension, and other variables, ensuring the wire is drawn to the exact specifications required. By integrating these technologies, manufacturers can achieve higher precision in wire diameter, surface smoothness, and overall uniformity, which are essential for producing high-quality wire.

The drawing speed is another key factor influencing the quality of the finished product. While high-speed drawing is often necessary to meet production demands, it must be balanced with the need for controlled tension and smooth feeding. Steel Wire Drawing Machines that feature high-speed capabilities, like those used in advanced manufacturing plants, ensure that wire is drawn quickly without sacrificing quality. However, the speed must be carefully calibrated to avoid over-stretching or breaking the wire, which can lead to defects. Thanks to automated controls, modern machines are able to maintain optimal drawing conditions throughout the production run.

Another factor that significantly impacts the quality of the wire is the capstan quality. Steel Wire Drawing Machines with high-quality capstans provide excellent support for the drawing process. The capstan ensures that the wire is evenly pulled through the dies, maintaining uniformity in diameter and surface quality. The durability of the capstan is crucial because a poorly maintained or low-quality capstan can result in uneven drawing, leading to inconsistent wire properties and a subpar final product. By investing in a machine with a high-quality capstan, manufacturers ensure both the longevity of the equipment and the consistency of the wire output.

Equally important is the role of wire surface finish, which is directly influenced by the drawing process. High-end Steel Wire Drawing Machines are designed to minimize surface defects such as scratches, kinks, or rough textures. The smooth, consistent tension applied throughout the drawing process, coupled with the precise control provided by the PLC/HMI system, ensures that the wire emerges with an ideal surface finish. For industries where the wire’s appearance is just as important as its strength—such as in automotive or electrical applications—a smooth finish is essential to maintain high-quality standards and prevent product rejection.

In conclusion, modern Steel Wire Drawing Machines provide unparalleled control over the wire drawing process, enabling manufacturers to produce wire that meets rigorous quality standards. From precision drawing speed adjustments to ensuring a smooth finish and high tensile strength, these machines are designed with quality control in mind. By investing in state-of-the-art equipment, manufacturers can not only improve the quality of their products but also enhance their operational efficiency and competitiveness in the market. Whether you’re producing fine wire for electronics or heavy-duty wire for construction, having the right Steel Wire Drawing Machine can make all the difference in achieving the quality and consistency your customers demand.

ติดต่อเรา